>>>>>型号:CB06551 伺服驱动器 多种归航模式

【功能描述】

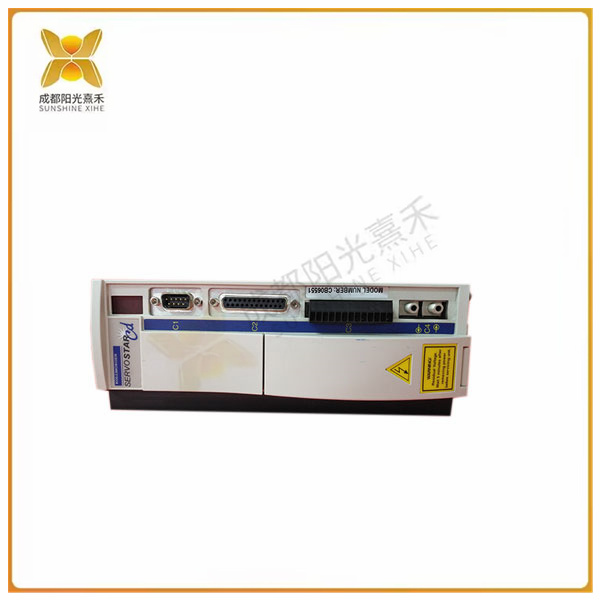

CB06551 PRD-B040SSIB-63 KOLLMORGEN 伺服驱动器

特点

CE,UL,cUL认证

直接电网运行,230V ~ 480V AC

输出电流 1.5A 到 20A

制动

集成再生电路(高达 20A)

配有集成电源滤波器(多达 20A),所有屏蔽直接连接至放大器

在住宅区使用伺服放大器时,本产品可能造成高频干扰。 用户必须进行额外的过滤器。

高达 20A,适用于 300mm 开关柜

使用安装软件通过 PC 进行操作

用于步进控制器、主-从动运行、电子齿轮的集成接口

集成位置控制器,配有用于存储 255 个运动任务的存储器 智能定位:

运动轮廓控制

定位控制

限制振动控制

多个运动任务的连接控制

绝对和相对运动控制

多种归航模式

编码器仿真可选择增量式或绝对值式

多种反馈系统:

旋转变压器,多达 36 极

通信编码器

带 Hall 的增量或正弦编码器

带 EnDat/HIPERFACE/BISS 的正弦编码器

无数据磁道的正弦编码器

增量编码器 A正交B

CB06551 PRD-B040SSIB-63 伺服驱动器是现代运动控制的重要组成部分,被广泛应用于工业机器人及数控加工中心等自动化设备中。尤其是应用于控制交流永磁同步电机的伺驱动器已经成为国内外研究热点。当前交流伺服驱动器设计中普遍采用基于矢量控制的电流、速度、位置三闭环控制算法。该算法中速度闭环设计合理与否,对于整个伺服控制系统,特别是速度控制性能的发挥起到关键作用在伺服驱动器速度闭环中,电机转子实时速度测量精度对于改善速度环的转速控制动静态特性至关重要。CB06551 PRD-B040SSIB-63 为寻求测量精度与系统成本的平衡,一般采用增量式光电编码器作为测速传感器,与其对应的常用测速方法为M/T测速法。M/T测速法虽然具有一定的测量精度和较宽的测量范围,但这种方法有其固有的缺陷,主要包括:1)测速周期内必须检测到至少-个完整的码盘脉冲,限制了最低可测转速;2)用于测速的2个控制系统定时器开关难以严格保持同步,在速度变化较大的测量场合中无法保证测速精度。因此应用该测速法的传统速度环设计方案难以提高伺服驱动器速度跟随与控制性能

>>>>>型号:CB06551 伺服驱动器 多种归航模式

【英文介绍】

CB06551 PRD-B040SSIB-63 KOLLMORGEN servo driver

peculiarity

CE, UL, cUL certification

Direct grid operation, 230V ~ 480V AC

Output current 1.5A to 20A

immobilize

Integrated regenerative circuit (up to 20A)

With an integrated power filter (up to 20A), all shields are connected directly to the amplifier

When the servo amplifier is used in residential areas, this product may cause high-frequency interference. Users must perform additional filters.

Up to 20A for 300mm switchgear

Use the installation software to operate from a PC

Integrated interface for stepper controllers, master-slave operation, and electronic gears

Integrated position controller with memory for storing 255 moving tasks Intelligent positioning:

Motion profile control

Positioning control

Restricted vibration control

Connection control of multiple motion tasks

Absolute and relative motion control

Multiple homing modes

Encoder simulation can be either incremental or absolute

Multiple feedback systems:

Rotary transformer, up to 36 poles

Communication encoder

Incremental or sinusoidal encoder with Hall

Sine encoder with EnDat/HIPERFACE/BISS

Sinusoidal encoder with no data track

Incremental encoder A orthogonal B

CB06551 PRD-B040SSIB-63 servo drive is an important part of modern motion control, which is widely used in industrial robots and CNC machining centers and other automation equipment. Especially, the actuator used to control AC permanent magnet synchronous motor has become a research hotspot at home and abroad. The current, speed and position three closed-loop control algorithms based on vector control are widely used in the design of AC servo drivers. Whether the speed closed-loop design in the algorithm is reasonable or not plays a key role in the whole servo control system, especially in the performance of speed control. In the servo drive speed closed-loop, the real-time speed measurement accuracy of the motor rotor is very important to improve the dynamic and static characteristics of speed control of the speed loop. CB06551 PRD-B040SSIB-63 In order to seek the balance between measurement accuracy and system cost, incremental photoelectric encoder is generally used as the speed measurement sensor, and the corresponding common speed measurement method is M/T speed measurement. Although M/T velocity measurement method has a certain measurement accuracy and a wide measurement range, but this method has its inherent defects, mainly including :1) the speed measurement cycle must detect at least - a complete code pulse, limiting the minimum measurable speed; 2) The timer switches of the two control systems used for speed measurement are difficult to maintain strict synchronization, and the accuracy of speed measurement cannot be guaranteed in the measurement occasions with large speed changes. Therefore, it is difficult to improve the performance of servo drive speed following and control by using the traditional speed loop design method

>>>>>型号:CB06551 伺服驱动器 多种归航模式