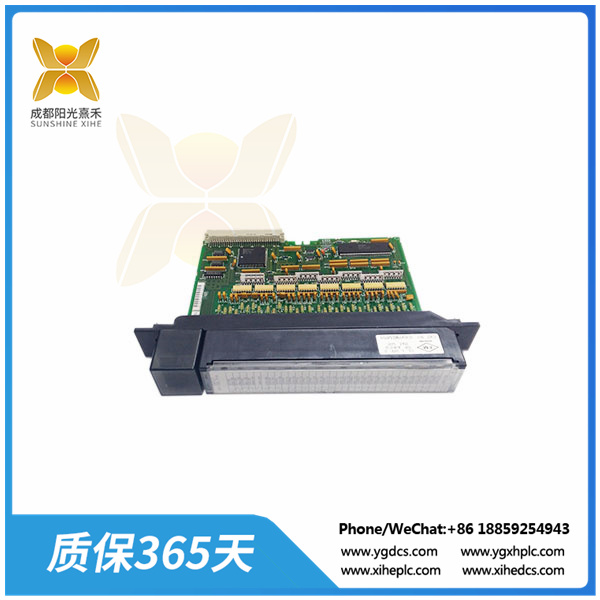

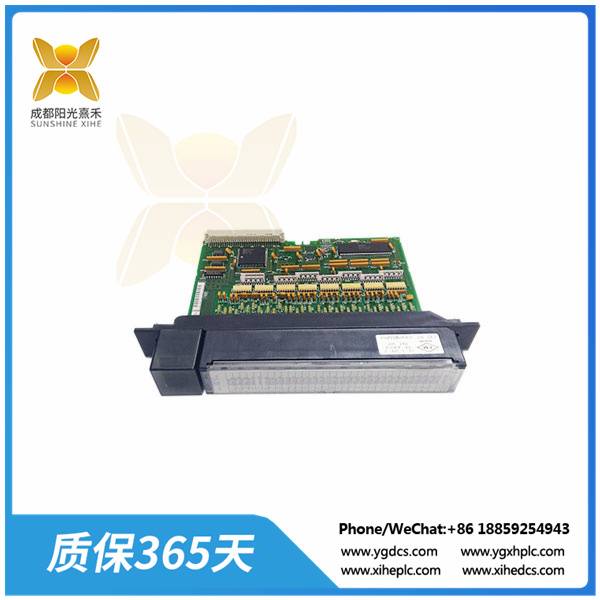

IC697BEM713 | 总线扩展模块 | 实现精确的过程控制和优化

型号:IC697BEM713

产品描述 总线扩展模块 (BEM)

制造者 GE Fanuc / 艾默生自动化

槽宽 单插槽

系列 90-70系列

安装位置 90-70 系列 CPU 底板

产品类型 总线扩展模块

描述: IC697BEM713是 90-70 系列总线扩展模块,来自 Emerson Automation,前身为 GE Fanuc。该模块专门用于总线发送器模块,具有高性能并行编程器接口,用于最大限度地提高主机 CPU 的 I/O 模块容量。它有一 (1) 个用于编程的并行端口和一 (1) 个扩展端口输出,用于菊花链连接到其他总线接收器模块。它具有三 (3) 个状态 LED 指示灯,例如 OK、PGMR Active 和 Bus Active 指示灯。

IC697BEM713 总线扩展模块是一种在工业自动化系统中用于扩展总线信号或功能的设备。根据不同的分类方式,总线扩展模块可以有多种类型,例如ZCAN总线扩展模块、EtherCAT扩展模块、ZMIO300扩展模块等。

这些模块的主要功能包括:

实时获取各种传感器信号,并与执行器进行协调和控制,从而实现自动化生产和高效运行。

在工业过程控制中,用于监测和控制参数,如温度、压力、流量和液位,实现精确的过程控制和优化。

采集和记录工业自动化系统中的各种数据,如生产过程中的计数、速度和质量数据,用于分析和优化生产效率、质量控制和设备维护。

用于实时监测设备状态和信号,以便及时诊断故障并触发报警,减少停机时间和维修成本。

Model: IC697BEM713

Product Description Bus Extension Module (BEM)

Manufacturer GE Fanuc/Emerson Automation

Slot width single slot

Series 90-70 series

Installation Position 90-70 series CPU mainboard

Product Type Bus expansion module

Description: The IC697BEM713 is a 90-70 series bus expansion module from Emerson Automation, formerly GE Fanuc. This module is specifically designed for bus transmitter modules with a high performance parallel programmer interface to maximize the I/O module capacity of the host CPU. It has one (1) parallel port for programming and one (1) expansion port output for daisy-chaining to other bus receiver modules. It features three (3) status LED indicators such as OK, PGMR Active and Bus Active indicators.

The IC697BEM713 bus extension module is a device used to extend bus signals or functions in industrial automation systems. According to different classification methods, there are many types of bus extension modules, such as ZCAN bus extension module, EtherCAT extension module, ZMIO300 extension module and so on.

The main functions of these modules include:

Various sensor signals are obtained in real time and coordinated and controlled with actuators to achieve automated production and efficient operation.

In industrial process control, it is used to monitor and control parameters such as temperature, pressure, flow and level for precise process control and optimization.

Collect and record various data from industrial automation systems, such as counting, speed and quality data during the production process, for analyzing and optimizing production efficiency, quality control and equipment maintenance.

It is used to monitor equipment status and signals in real time in order to diagnose faults in time and trigger alarms, reducing downtime and maintenance costs.