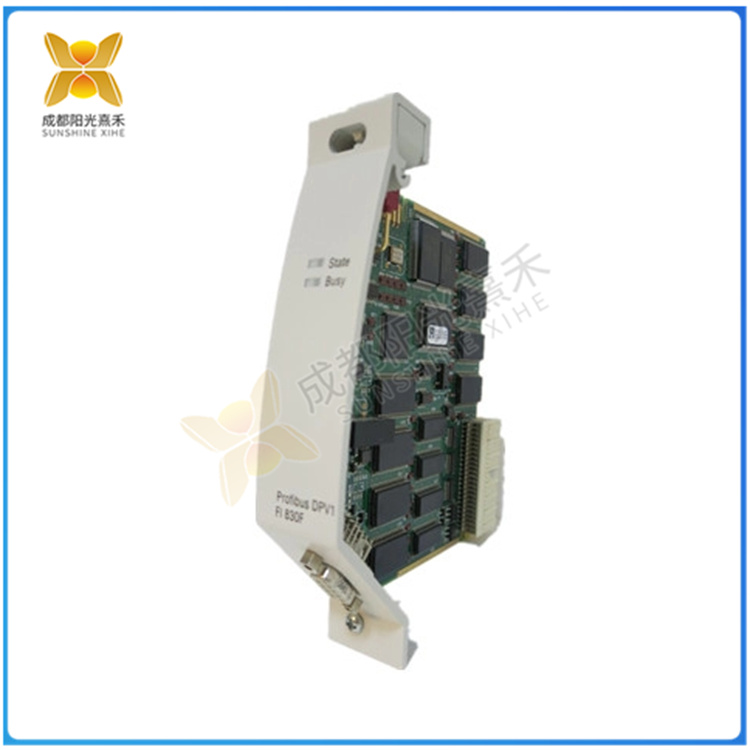

>>>>>型号:FI830F DCS模块 用于控制工业环境

【功能描述】

FI830F 是一种DCS模块。

DCS系统用于控制工业环境中的各种设备和过程。

它主要负责工件坐标系的定义和管理。工件坐标系是一个相对于大地坐标系的参考框架,用于描述工件的位置和姿态。

在机器人操作过程中,工件坐标系是非常重要的,因为它帮助机器人精确地定位和识别工件,从而实现精确的操作和加工。

FI830F模块提供了灵活和强大的功能,支持定义多个工件坐标系。这意味着机器人可以处理多个不同的工件,

或者处理同一工件在不同位置的不同副本。这对于提高机器人的工作效率和灵活性非常有帮助。通过编程,

操作人员可以在FI830F模块中创建目标点和轨迹路径,使机器人能够按照预定的路径和速度进行操作。

FI830F模块还提供了与其他设备和系统的集成能力。它可以通过各种通信接口和协议与其他控制系统、

传感器和执行器进行连接和通信,实现数据的共享和协同工作。这使得FI830F模块能够与其他工业自动化设备无缝集成,

形成一个完整的工业自动化解决方案。

>>>>>型号:FI830F DCS模块 用于控制工业环境

【英文介绍】

FI830F is a DCS module.

DCS systems are used to control a variety of equipment and processes in industrial environments.

It is mainly responsible for the definition and management of the workpiece coordinate system.

The workpiece coordinate system is a reference frame relative to the geodetic coordinate system, which is

used to describe the position and attitude of the workpiece. In the process of robot operation, the workpiece

coordinate system is very important, because it helps the robot to accurately locate and identify the workpiece,

so as to achieve accurate operation and machining.

The FI830F module provides flexibility and power to define multiple workpiece coordinate systems. This means

that the robot can handle multiple different workpieces, or handle different copies of the same workpiece

in different locations. This is very helpful for improving the work efficiency and flexibility of the robot.

By programming, the operator can create target points and trajectory paths in the FI830F module, enabling

the robot to operate at a predetermined path and speed.

The FI830F module also provides integration with other devices and systems. It can connect and communicate

with other control systems, sensors and actuators through various communication interfaces and protocols to realize

data sharing and collaborative work. This enables the FI830F module to be seamlessly integrated with other industrial automation

equipment to form a complete industrial automation solution.

>>>>>型号:FI830F DCS模块 用于控制工业环境